Fume cupboards

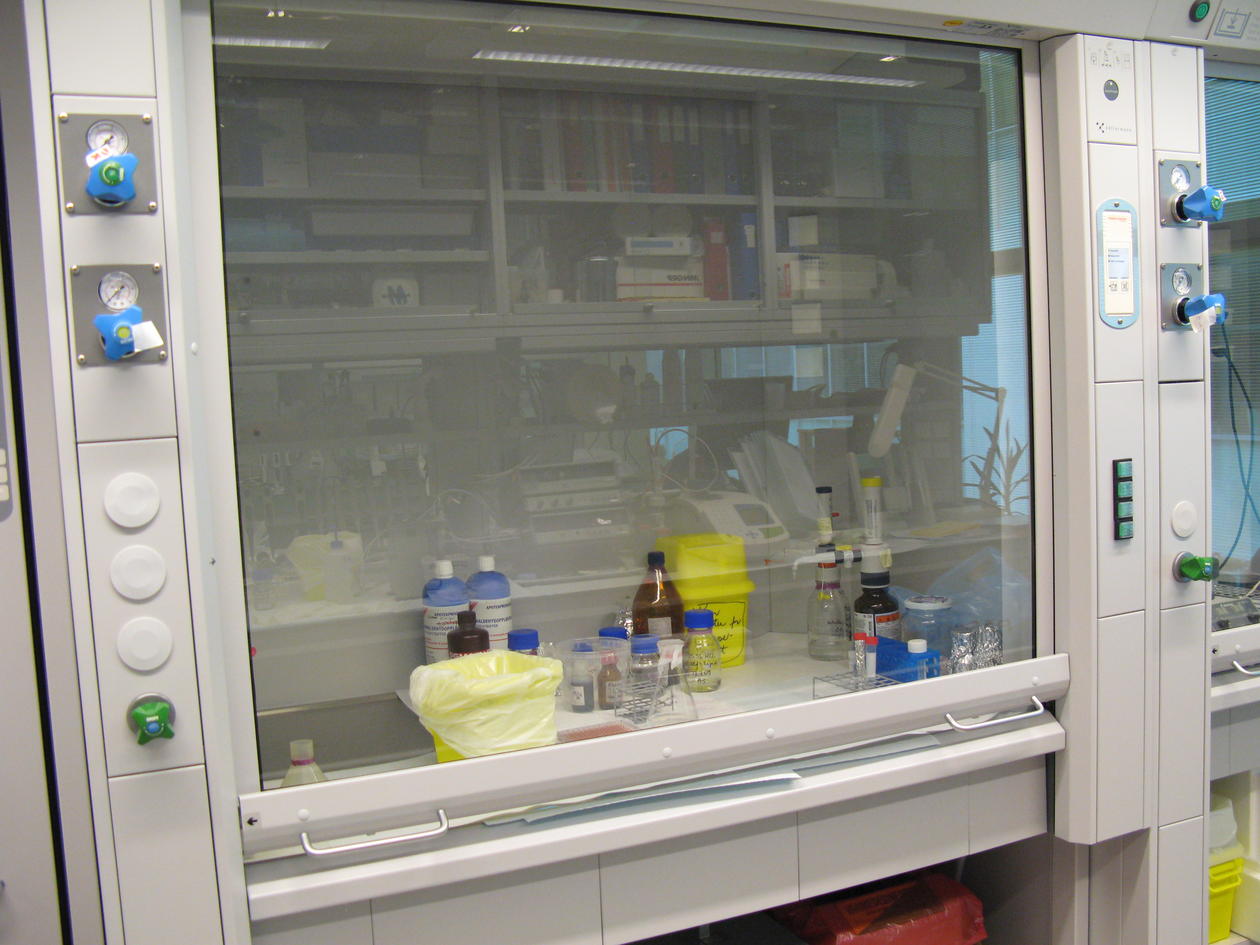

The fume cupboard is the most important protective device in the laboratory.

Main content

The fume cupboard should eliminate the inhalation of vapours and dust that are irritating or harmful to health, while at the same time preventing the development of explosive gas mixtures.

There are four different types of “controlled extraction” in laboratories: fume cupboards, extraction cabinets of the LAF (laminar air flow) type, glove boxes with extraction and flexible extraction by hood. Only fume cupboards are discussed below. A number of conditions must be met in order for the fume cupboard to remove contaminants successfully and effectively. See the menu item below.

The fume cupboard is not a storage cupboard for chemicals. Volatile chemicals must be stored in a suitably ventilated cupboard.

- Guidelines for annual checks on fume cupboards (NO)

- Precautions and safety measures

- Ergonomics in the laboratory

Air flow in fume cupboards

In order for the fume cupboard to remove contaminants successfully and effectively:

- The air flow from the cupboard must be a minimum of 140 litres/second (500 m3/h).

- The air velocity in the hatch opening in the direction facing into the cupboard must be a minimum of 0.5 metres/second.

- The cupboard must be equipped with suction at the rear, both at the top and the bottom of the cupboard.

Based on 140 l/s and with a cupboard opening, in the opening of a normal fume cupboard an air velocity of 0.5 m/s will be achieved with a hatch opening of 28 cm (hatch approx. one-third open). This is the cupboard’s safety height (working height).

If the hatch opening exceeds 28 cm there is a danger that vapours and dust hazardous to health may leak out. The risk will vary depending on vapour pressure and the specific gravity of the various vapours, so that the air velocity in the hatch opening may, for example, vary from 0.25–1 m/s with the same “safety margin”. As it is not always known or certain which substances will be used in the cupboard, plans should be made on the basis of a capacity that entails a minimum of 0.5 m/s.

Location of fume cupboards

In order for the fume cupboard to remove contaminants successfully and effectively:

- Establish a safety zone around the cupboard. Typically, this will be 0.5 metres from the ceiling and wall and 1 metre in front.

- Place the cupboard in such a way that a laminar air flow is established in the cupboard opening. It takes very little turbulence to “drag” impurities from the cupboard and into the room. Turbulence arises in the cupboard opening if the cupboard is placed close to ventilation windows, doors or walkway zones in the laboratory, or when the cupboard is located incorrectly in respect of the air flow in the room.

Correct use of fume cupboards

In order for the fume cupboard to remove contaminants successfully and effectively you should:

Locate the work (volatile liquids, dust-generating material, etc.) as close to the centre of the cupboard as possible. Generally, the suction in the cupboard is best here.

Examine the safety height of the hatch. This will normally be 25–30 cm. During work, the hatch opening should not be any higher. Where this nonetheless is the case, the volume of air from the cupboard must be increased above normal levels. Some cupboards feature automatic regulation of the volume of air according to the hatch opening height (constant flow). Check this with the operating staff. The hatch must always be down when the cupboard is not in use.

Move quietly and calmly when working in the cupboard. This avoids creating turbulence and getting contaminated air into the breathing zone of the operator.

Store as few bottles and as little equipment as possible in the cupboard. The fume cupboard is not a storage cupboard. Bottles and equipment destroy the laminar flow picture within the cupboard, thus reducing the effectiveness.

Never bend your head into the cupboard; reassess the method of working or setup of the experiment.

Choose your working position (sitting or standing) on the basis of the risk of splashes from corrosive liquids and the duration of the work. It is preferable to work in a standing position where there is a danger of splashes or spillages from concentrated acids and bases.

Fault warning

In order to provide reassurance to the user that the fume cupboard is working correctly, a warning indicator must be fitted that warns in the event of a fault. In this context, a “fault” is when the air velocity in the hatch opening is not sufficient to prevent the leakage of contaminated air into the room. This can happen when leaks occur in the extraction ducts (suction of infiltrated air), a fan belt snaps or the system is closed down, e.g. due to a power failure, operational failure or planned servicing. For existing cupboards without a warning indicator, as a minimum requirement a piece of weighing paper should be used and “taped” to the underside of the hatch. When the cupboard is extracting, the weighing paper will draw across the cupboard. A wide range of warning indicators is available on the market. These include: the Vaneometer, vane anemometer, hot-wire anemometer and low velocity anemometer. Contact your laboratory equipment supplier for a price quote.

All fume cupboards must have a warning indicator fitted featuring a sound/light that warns the user when the air velocity in the opening is below 0.5 m/s.

Requirements for new fume cupboards

Requirements for new fume cupboards

These requirements will not be fully comprehensive for work with hydrofluoric acid, perchloric acid, radioisotopes or explosives. In these cases, entirely specific requirements apply in respect of resistance to corrosion, radiation shielding and/or deformation.

The following requirements must be applied when purchasing a new fume cupboard:

- The cupboard must undergo functional testing (testing of the fume cupboard) in accordance with NS-EN 14175-2. The cupboard must have a safety factor (E-value) of more than 95%. Documentation must be provided.

- The air flow from the cupboard must be a minimum of 140 litres/second (500 m3/h). The air velocity measured in the cupboard opening must be a minimum of 0.5 m/s. The air supply system must have the capacity to replace the extracted volume of air.

- The cupboard must have a documented aerodynamic design for optimal flow pattern and energy consumption. A spoiler or equivalent must be fitted to ensure the satisfactory entrainment of gases from the bottom plate in the cupboard.

- The cupboard and hatch must be of correct ergonomic design (NO).

- A warning indicator must be fitted to the cupboard in case of any functional fault.

- The level of noise from the cupboard must be specified by the supplier and assessed by the user. We recommend a noise level below 40 dB(A) at a hatch opening of 30 cm and an air velocity of 0.5 m/s.

- The components and materials of the cupboard must be resistant to the effects in question. These effects may be chemical (acids, bases, organic solvents, disinfectant liquids, etc.), mechanical (knocks, pressure, friction), thermal (use of Bunsen burner, liquid nitrogen, etc.) and physical (UV light, laser, etc.)Danish standard DS 457 contains a summary of surface unit materials and the various effects.

- The surface unit in the cupboard must be designed so that spillages do not leak out of the cupboard. The glass in the hatch opening must be laminated glass.

- The cupboard may additionally be fitted with a washbasin and sockets for gas and electricity as required.

Annual checks on fume cupboards

In order to provide reassurance to users that the fume cupboard is removing contaminants well and effectively, the cupboard must undergo an annual check. The University of Bergen has drawn up its own guidelines for annual checks on fume cupboards.

Check that:

- Total air flow through the cupboard is >= 140 l/s and with hatch opening

- The air velocity in the hatch opening in the direction facing into the cupboard is >= 0.5 metres/second

- The hatch raising system (wire and counterweights) is in good condition

- The lighting in the cupboard is satisfactory (500–1000 lux)

- Taps/switches for water, gas and electricity are in good condition

- The warning indicator on the cupboard (where fitted) works satisfactorily

Cupboards thus checked should be labelled to show the date on which the check was performed and the signature of the person who performed the check.

The institute/department should incorporate fume cupboard checks into its systematic HSE work in the laboratory. The issue of who is responsible for carrying these out in practice should be discussed with the operations manager/section manager. HSE Section will be able to assist with this work and can provide, among other things, measuring equipment for measuring the air velocity in the hatch opening.

Fume cupboard testing – requirements on suppliers

Fume cupboards should be tested in respect of the following factors:

- Safety factor, calculated on the basis of measurements using tracer gas, or the contamination in question.

- Pressure drops across the extractor fans at varying fan speeds and hatch opening.

- Noise measurements at varying fan speeds and hatch opening.

- Measurements of air velocity in the hatch opening at current settings.

- Illumination level (lux) measured on the surface unit (this is at variance with the Nordtest method, but it is desirable for this to be carried out.)

The test report must include:

- Name and address of the testing laboratory.

- Identification number of the test.

- Name and address of the person who ordered the test.

- Purpose of the test.

- Description of measuring equipment and measuring criteria.

- Name and address of the manufacturer of the fume cupboard.

- Name/product number and age of the fume cupboard.

- Description and diagram of the fume cupboard.

- Date on which the test is performed.

- Measurement method, including a description of measuring points.

- Conditions that may affect the test (air temperature, humidity, etc.)

- All deviations from the test method.

- Test results.

- Inaccuracies/uncertainty in the various results.

- Date on which test report completed and signature.

Ergonomic requirements of fume cupboards

Please refer to separate web pages for ergonomics in the laboratory.

References

- Working in laboratory (NO)

- NS-EN 14175 Fume cupboards

- NS-EN 14175 part 1: Vocabulary

- NS-EN 14175 part 2: Safety and performance requirements

- NS-EN 14175 part 3: Type test methods

- NS-EN 14175 part 4: On-site test methods

- NS-EN 14175 part 5: Recommendations for installation and maintenance (in prep.)

- NS-EN 14175 part 6: Variable air volume fume cupboards (in prep.)